- Home

- Service And Parts

Field Service and Maintenance

Field Service & Maintenance

Equipment and competence for safe and efficient plant operation

Our Expert Technical Staff

- Coordinated support from the Nederman MikroPul Engineering, Manufacturing, Parts and Applications staff to address

- Highly experienced customer service staff to handle your questions and requests

- Equipment asessments for the purposes of repair or performance optimization

- Highly trained technicians for field repairs of all baghouse or dust collector makes

- Contract service plans and pricing.

- Preventive maintenance programs.

- Upgrades and retrofits for a wide variety of dust collection equipment, including Nederman MikroPul, Nederman Pneumafil, Donaldson, MAC, Torit, Camfil Farr, UAS, and others.

Typical baghouse maintenance schedule

Daily Maintenance Checks

- Check Pressure drop

- Check cleaning system for air leaks or stuck diaphragms'

- Check that dust is being removed from hoppers

- Check for visual emissions

- Check Triboflow readings for any signs of bag leak

- Check levels of totes and empty when necessary

Weekly Maintenance Checks

- Check all moving parts on dust conveying systems

- Check air supply lines and compressor's

- Check Photohelic gauges and use air to blow out lines when needed

- Check that cleaning system is operating properly

- Check all drive systems Belts and Chains, ensure proper guarding

Monthly Maintenance Checks

- Spot check bag conditions

- Check all moving parts on shaker baghouse's

- On positive pressure Baghouse's inspect fans for build up and address if needed

- Check condition of baghouse hoppers and components

Quarterly Maintenance Checks

- Spot check bags doing dye test

- Visually spot check bags and cages for condition

- Check dampers for proper operation

- Check door gaskets for a good seal

- Check baffle plates for wear, and structure

- Calibrate leak detection ( Triboflow )

Semiannual Maintenance Checks

- Check all components for wear or pluggage ( Hoods,Trails, Fan housings )

- Check all Structure related components

Annual Maintenance Checks

- Check all structure bolts, and welds

- Check Hoppers for corrosion

- Check condition of paint to try and prevent corrosion

- Emissions check

Downloadable Documents

Nederman MikroPul Repair, Upgrade, and Maintenance Services

Parts & Service Terms and Conditions

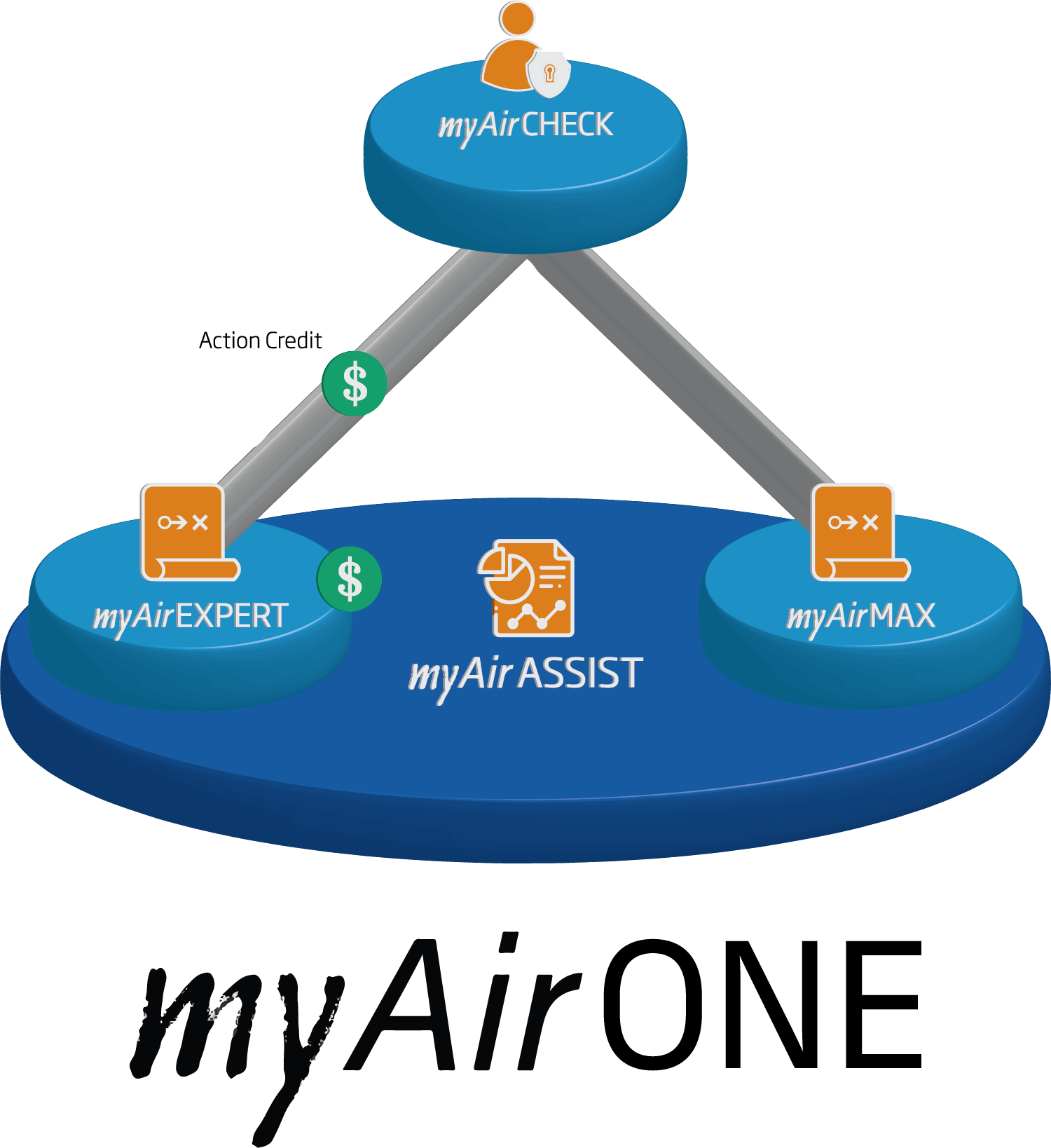

myAir ONE

For a comprehensive long term service program for the whole site across all brands of dust collector equipment, choose myAir ONE

Contact us to create your custom solution

Call us at: 704-859-2723 or fill out the form below.