- Home

- Industries

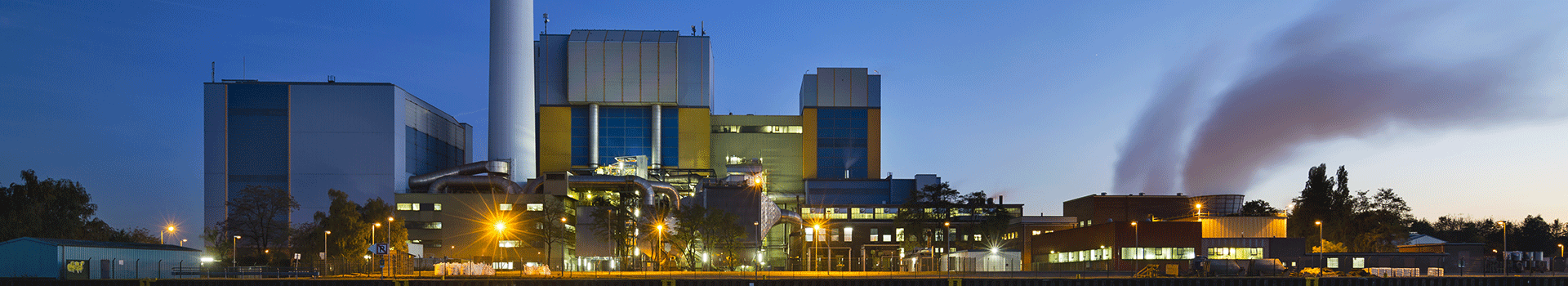

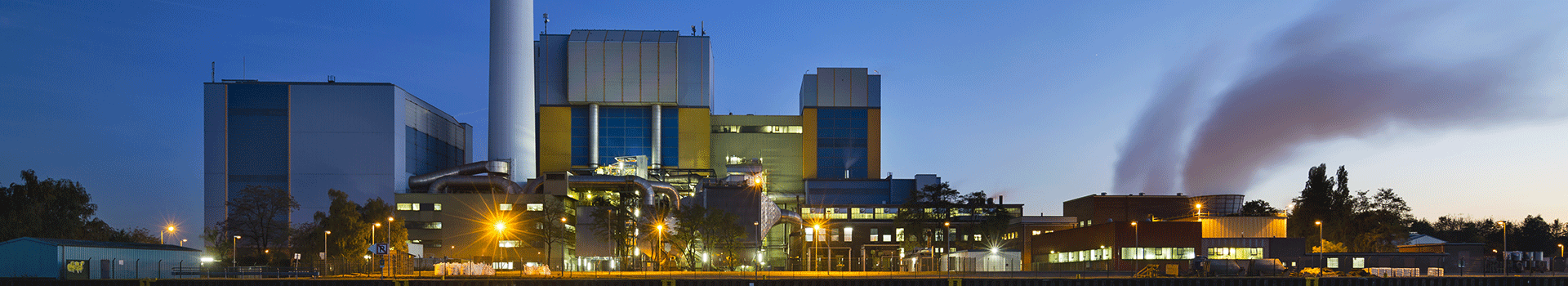

Waste to Energy

Waste to Energy

Incineration plants produce exhaust gases that are loaded with a range of pollutants. These pollutants are separated from the air in various processes before the cleaned exhaust air leaves the plant safely via the stack.

FLUE GAS CLEANING

Incineration plants produce exhaust gases that are loaded with a range of pollutants. These pollutants are separated from the air in various processes before the cleaned exhaust air leaves the plant safely via the stack.

The legally required maximum emission limits for these processes are a challenge for many companies in the industry. We are happy to support in mastering these tasks. Nederman MikroPul is a reliable and consistent partner to the industry all over the world.

Based on the individual requirements and conditions of each plant, we develop customized concepts for exhaust gas treatment.

The following factors are taken into account in our individual concepts for exhaust gas cleaning:

- Compliance with the legal emission values

- Investment and operating costs

- Costs for additives and disposal

- Availability

- Available space (floor space, restrictions due to already defined building shape, etc.)

TYPICAL POLLUTANTS AND OUR APPLICATIONS

Various pollutants enter the combustion process through the fuel. These include oxidized combustion products such as SO2and NOx, substances such as hydrogen chloride and hydrogen fluoride, heavy metals, mercury and dioxins/furans. With specific flue gas cleaning processes (FGC), we separate these pollutants to subsequently dispose of them in accordance with local redulations.

Acidic Pollutants

Nitrogen Oxides

Organic Carbon Compounds

Mercury

Contact us to create your custom solution

Call us at: 704-859-2723 or fill out the form below.