- Home

- Industries

- Metals

Foundries Smelters

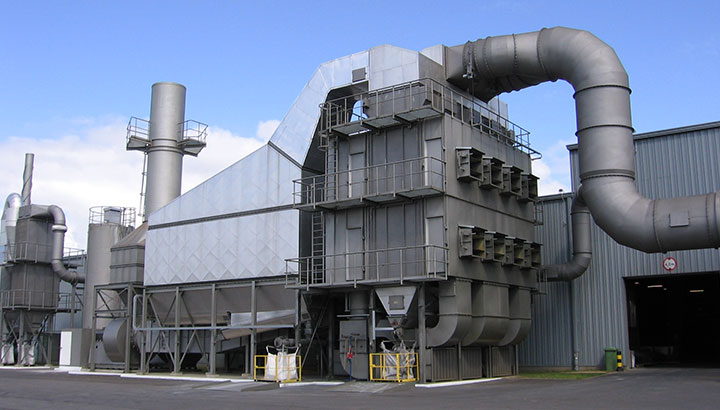

Foundry Dust and Fume Extraction Solutions

Keep operating and maintenance costs to a minimum with safe, clean and efficient production using complete solutions for dust and fume extraction at all stages in the foundry process.

Protect your production and employees from the toxic and acidic gases from foundry processes and meet or exceed emission level regulations. Our complete foundry and smelter dust and fume extraction solutions keep you protected from start to finish of your industrial process.

Dust collection from melting furnaces:

Melting furnaces produce harmful emissions. The hazardous emissions must be collected and filtered, and the acidic pollutant gases as well as dioxins/furans must be eliminated. Our solutions are specifically engineered for each type of melting furnace. Here are a few examples of how we extract dust and fume for different furnaces:

- Hot or cold blast cupolas, with extraction of furnace gas at the top or bottom, with additional oxygen injection, exhaust gases cooled by means of air-to-air coolers, with online cleaning of the cooling surfaces where applicable

- Induction furnaces, collection via hydraulic induction furnace hoods in all working conditions: charging, melting, holding, skimming, pouring and re-pouring. Emissions from magnesium treatment using the pour-over method can be collected either via the furnace hood or by roof-top extraction.

- Electric arc furnaces, emissions collected by direct extraction via the fourth hole cover and roof-top extraction

- Storage furnaces and channel-type furnaces, extraction for channel and forehearth with descending hoods, pivotable for easy access to the channels.

More Dust Collection and Gas Cooling solutions for foundry

- Sand reclamation for both resin-bonded and bentonite-bound sand

- Moulding lines

- Casting Aftertreatment

We ensure optimum dust collection with the lowest possible volumetric flow, thus minimizing investment and operating costs. Nederman MikroPul dust collection plants are highly efficient and designed for economic operation. Compliance with the maximum allowable concentrations prescribed by law and the statutory emission levels is assured.

Contact us to create your custom solution

Call us at: 704-859-2723 or fill out the form below.