Why should you treat gas turbine inlet air?

Air filtration provides protection against the effects of contaminated inlet air that would degrade gas turbine performance or life - erosion, fouling, corrosion and cooling passage plugging.

Due to its inherent design and the enormous amount of air consumed, any gas turbine is extremely sensitive to air quality.

For example, a GE Frame 7EA machine ingests 504,776 ACFM at ISO conditions. Even assuming the gas turbine is base load operating in a relatively clean air environment of, say, 0.02 grains / 1000 cubic foot, (45 micrograms / m3), during the course of each operational year, it ingests 758 lbs. (345 kg.) of atmospheric particulate matter.

Erosion

Both the axial compressor and the hot-gas-path parts can be affected by erosion from hard, abrasive particles, such as sand and mineral dusts. As these particles make contact with the compressor blades, they cut away a small amount of metal and the damage becomes permanent. In general, particles below 10 micrometer do not cause erosion, whereas particles 20 micrometer and above cause erosion when present in sufficient quantities.

Fouling

The efficiency of an axial compressor is dependent on, among other considerations, the smoothness of the rotating and stationary blade surfaces. These surfaces can be permanently roughened by erosion, but more frequently the roughening is caused by the ingestion of substances that adhere to the surfaces. These includes oil vapors, smoke and sea salt. A turbine’s output can be reduced by as much as 10% by compressor fouling. Fortunately, there are ways of removing these adhesive deposits from the compressor blades; damage from fouling is not permanent.

Corrosion

Wet deposits of sea salt, acids and other deleterious materials can cause compressor components to corrode, resulting in compressor blade pitting and rusting. Pitting causes a roughening of the airfoils with consequent permanent reduction in the aerodynamic performance of the compressor.

Hot-Section Corrosion

Possibly the single most important and frequently encountered consequence of inadequate air filtration is the ingestion of certain metals which, after combining with sulfur and / or oxygen during the combustion process, deposit on the surfaces of hot gas parts. Four metals are of primary concern; sodium (Na), potassium (K), vanadium (V) and lead (Pb). These metals, sulfates or oxides, cause the normally protective coating oxide film on hot-gas-path parts to be disrupted so the parts oxidize many times faster than normal.

Cooling Passage Plugging

Flow of cooling air through very small passages in the combustion liner and first stage nozzles is necessary to control the temperatures of these parts. Since the cooling air is extracted from the compressor of the gas turbine, contaminates in the inlet air are also present in the cooling air. If, due to inadequate air filtration, contaminants cause a buildup in the cooling passages, heat transfer is degraded and temperatures may increase to levels that cause cracking. Coal dust, cement dust and fly ash are particularly bad, since they tend to sinter.

Inlet Air Cooling

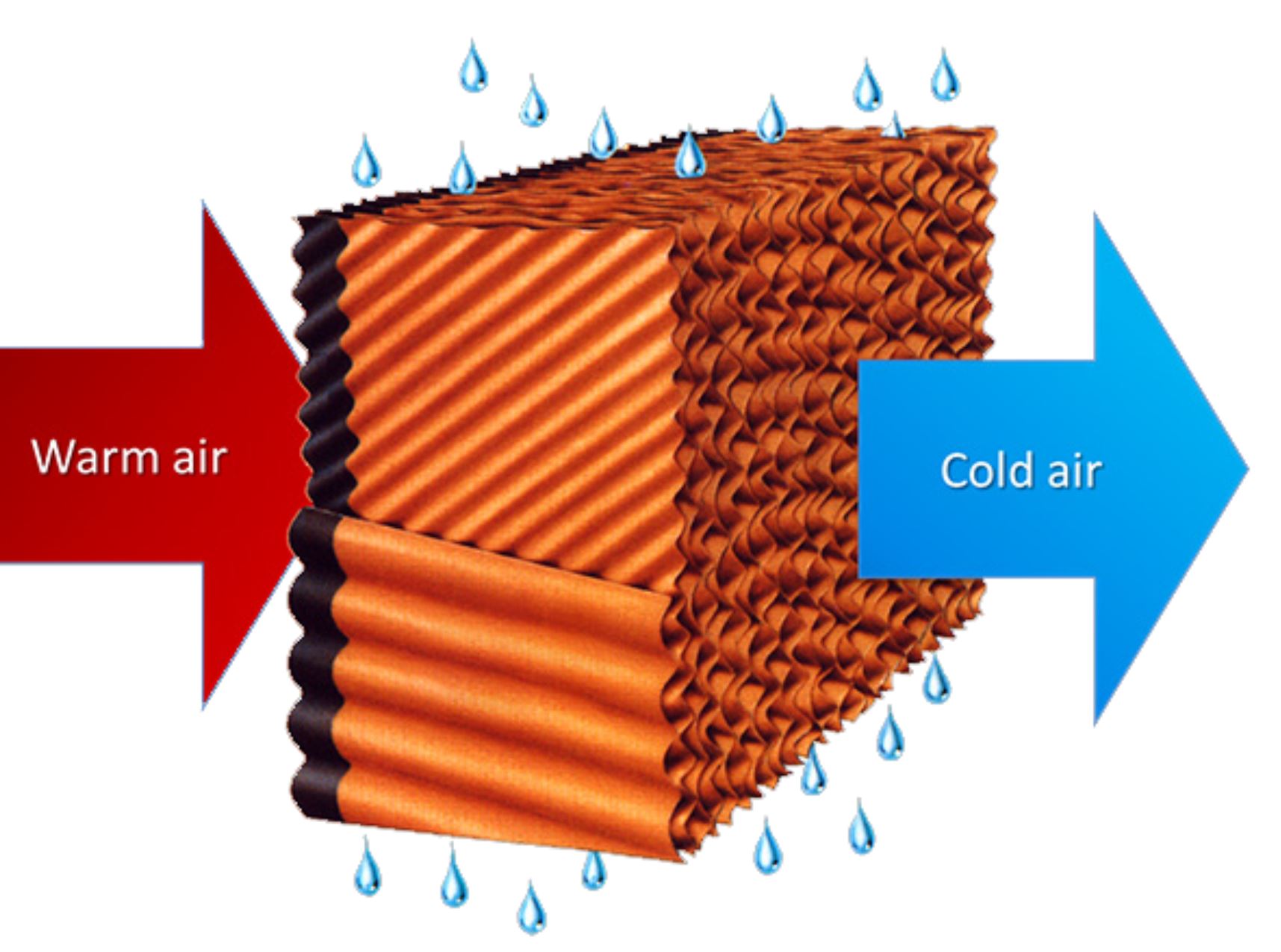

Figure 1: How Evap Cooling Works

Turbine output and heat rate are improved as compressor inlet temperature decreases. Lowering the compressor inlet temperature can be accomplished by incorporating an evaporative cooler or inlet chiller in the inlet air system. Cooled air, being denser, gives the machine a higher mass-flow rate and pressure ratio, resulting in an increase in turbine output and efficiency.

In addition, the use of an evaporative cooler improves the machine’s environmental impact. Increasing water vapor in the inlet air tends to lower the amount of oxides of nitrogen produced in the combustion process, lowering the machine’s emissions. There is also a small improvement in the dust loading due to the “air washing” effect as the air traverse the cooler.

Unlike evaporative coolers, the ambient wet bulb temperature does not limit a chiller. Achievable temperature is limited only by the capacity of the chilling device to produce coolant and the ability of the coils to transfer heat.

Steam and Water Injection for Power Augmentation

Injecting steam or water into the head end of the combustor for NOx abatement increases mass-flow and, therefore, output.

Steam injection for power augmentation has been an available option for over 30 years. When steam is injected, it can be introduced into the compressor discharge casing of the gas turbine as well as the combustor.

When either steam or water is used for power augmentation, the control system is normally designed to allow only the amount needed for NOx abatement until the machine reaches base (full) load, at which time additional steam or water can be admitted.

ANSI BI33.6 Ratings and Performance defines base load as operating at 8,000 fired hours per year with 800 hours per start. It also defines peak load as operating at 1,250 hours per year with five hours per start.

Figure 2: Schematic of water / steam injection into gas turbine combustion chambers

Inlet and Exhaust Losses

Inserting air filtration, silencing, evaporative coolers, chillers into the inlet or heat recovery devices in the exhaust causes pressure losses. Effects of these parasitic pressure losses are unique to each gas turbine design. However, as a rule of thumb, the following are typical of large heavy-duty machines:

4 inches (10 mbar) Water Column Inlet Drop Produces:

- 1.42 % Power output loss

- 0.45 % Heat rate increase

- 1.9 °F Exhaust temperature increases (1.1 °C)

4 inches (10 mbar) Water Column Exhaust Drop Produces:

- 0.42 % Power output loss

- 0.42 % Heat rate increase

- 1.9 °F Exhaust temperature increases (1.1 °C)

Figure 3: Turbine Performance vs Temperature Graph

Contact us to create your custom solution

Call us at: 704-399-7441 or fill out the form below.