- Home

- Service And Parts

MikroPul-Assist Remote Monitoring

MikroPul-Assist Remote Monitoring

MikroPul-Assist keeps a continuous watch on the dust collector performance. Client-defined notifications and visualization of performance trends support proactive maintenance efforts.

MikroPul-Assist solves problems like these

Our valued customers list these obstacles that may be overcome by using a remote monitoring technology:

- Emergency situations in the plant, e.g. stop production or fire

- Unable to plan maintenance task with enough advance notice

- Unscheduled downtime due to equipment failure

- Difficult in finding new employees with the right experience and skills

Added Benefits

Also, our customers list these potential extra benefits they can gain by using a remote monitoring technology:

- Communicate to Business Leaders that all processes are in control

- Achieve savings from the maintenance budget

- Take care of maintenance employees’ commitment to overtime or off-hours

- Have a stable and reliable service and maintenance partner who handles every need

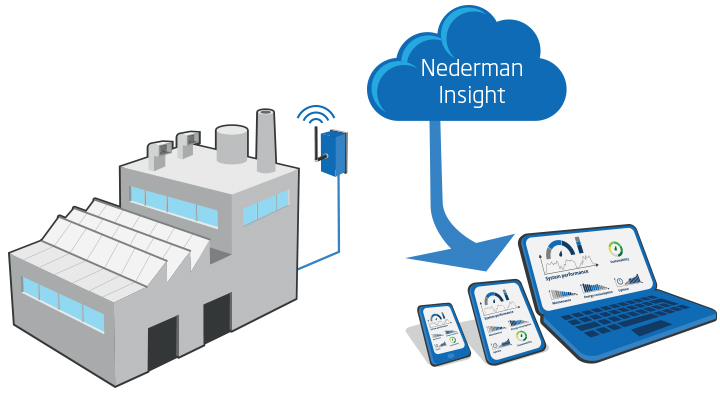

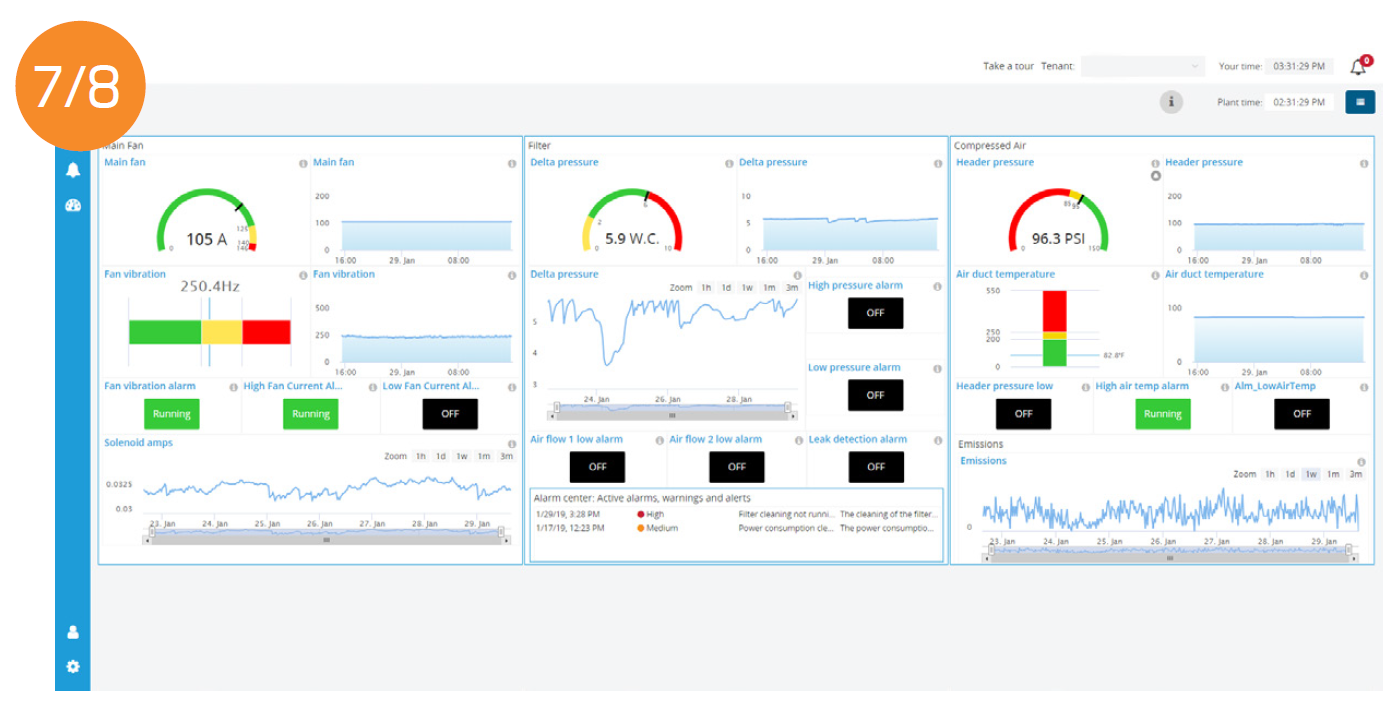

We harness the power of Nederman Insight to put filtration performance data in the palm of your hands. MikroPul-Assist combines filtration application expertise with data to give you a broader understanding of your dust filtration performance, expected parts and bag life, and energy savings. Here’s how it works:

- Sensors capture conditions in the filtration system

- Data is securely sent to the cloud via an IoT gateway

- You and your Nederman MikroPul technician can simultaneously view performance metrics using any smart device

- Auto-generated alerts notify key personnel to data anomalies

What is MikroPul-Assist?

MikroPul-Assist is a remote monitoring technology supported by expert MikroPul technicians and is available for both New and Existing collectors. We begin with the original sensing and control components of the dust collector and add a data acquisition sub-system. Then, we complete the system with Nederman Insight, the market-leading application providing cloud-based remote monitoring for dust collectors across the globe.

MikroPul-Assist keeps a continuous watch on the dust collector performance. Client-defined notifications and visualization of performance trends support proactive maintenance efforts.

Your dust collector’s information is read by our expert technical staff and we supply a regular status update. If there is a problem, we can recommend what action should be taken and when.

The result is improved uptime for your process, lower parts usage and predictive care so that you avoid unplanned or emergency repairs.

MikroPul-Assist, powered by Nederman Insight is the ideal collaboration of human and machine working together to improve uptime, mitigate risk, and save you money.

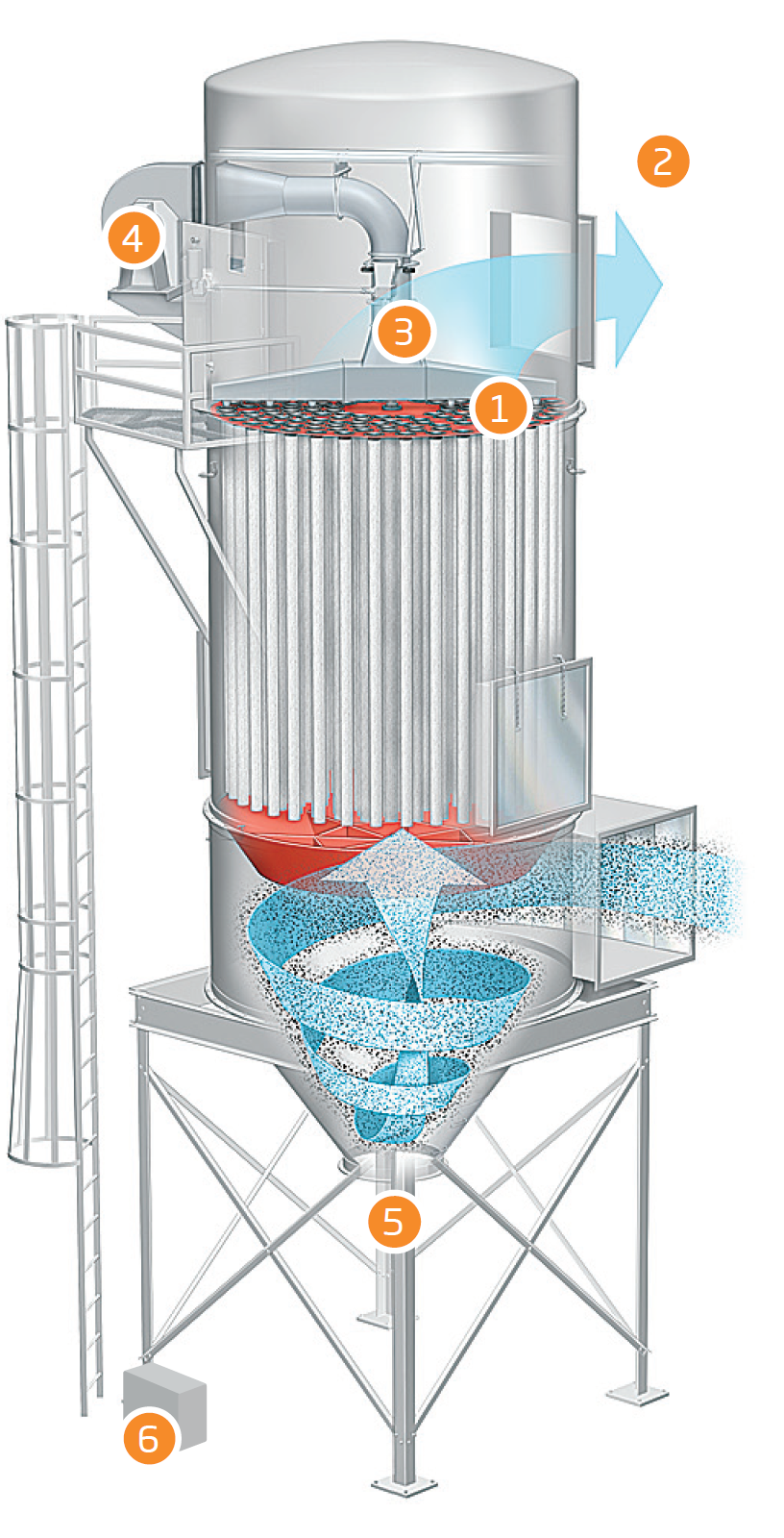

Enhanced Sensing Solutions for Pulse jet Dust Collectors

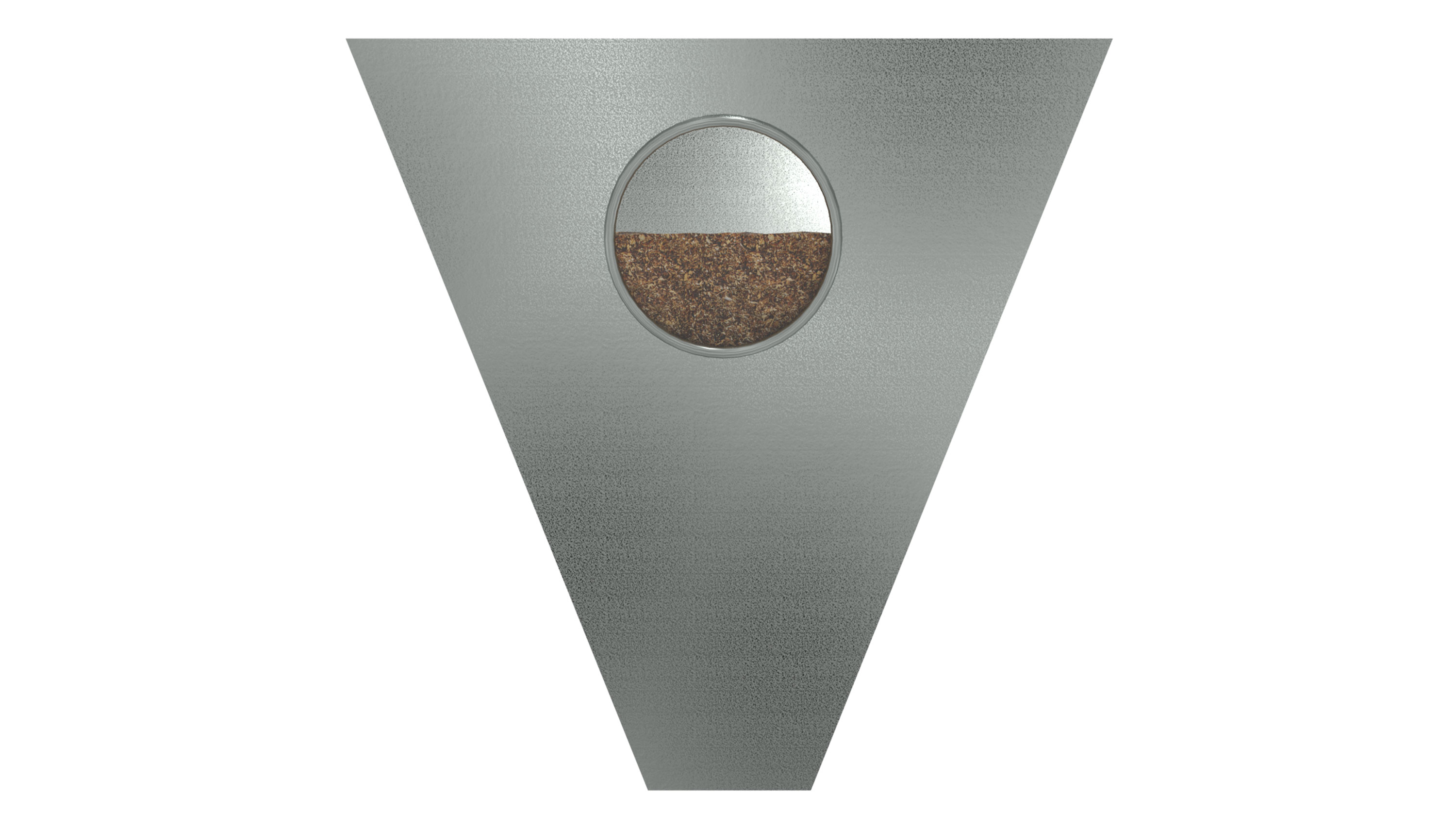

Hopper Level

Hopper Level Indicators are used to detect the presence (or absence) of material at predetermined points. Used to determine the material levels within your hopper, they can also be used to detect plugged conditions or backup of material into the collector.

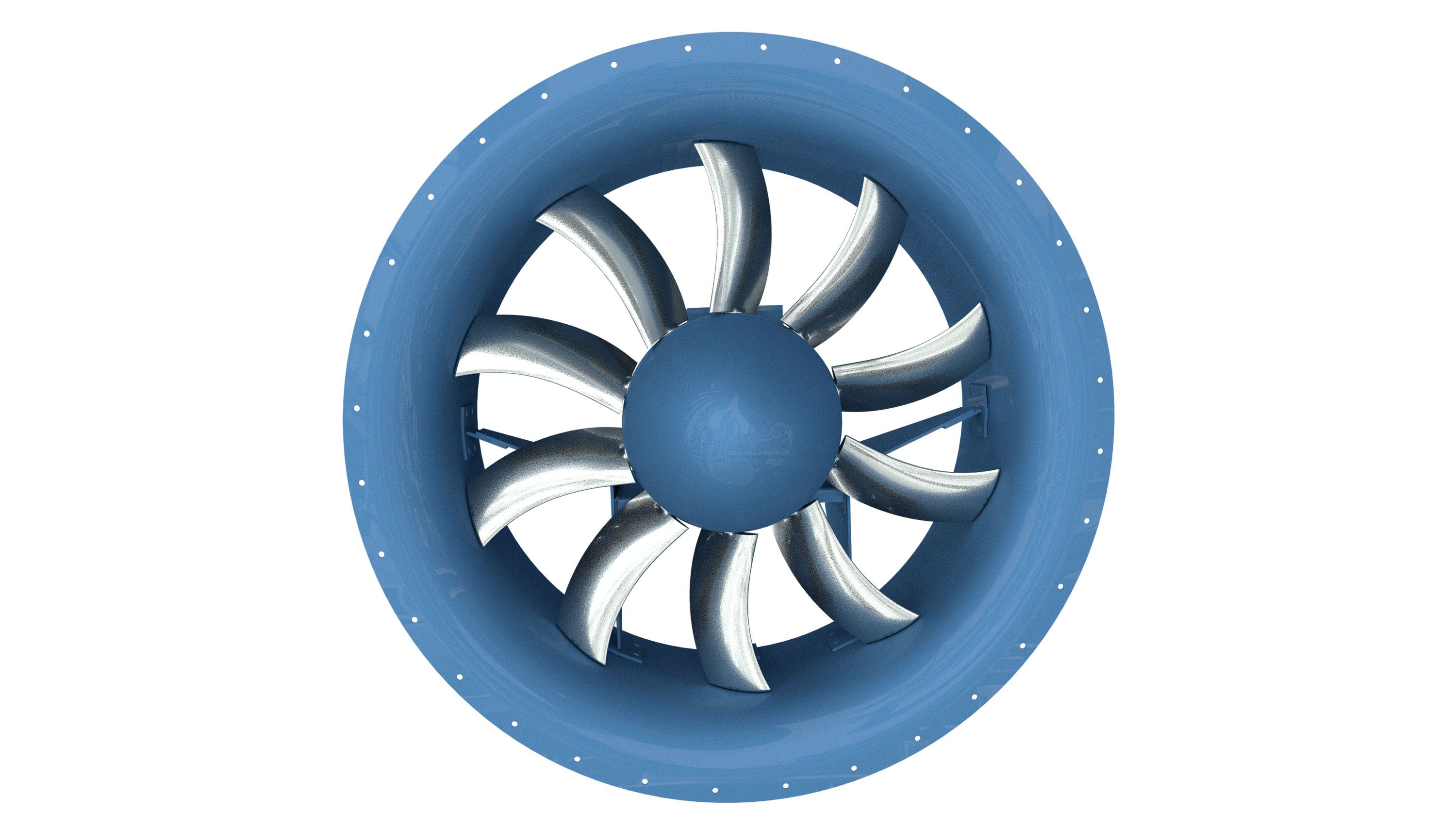

Fan Performance

Measuring fan vibration and bearing temperature provides an early warning for potential equipment faults. Changes in vibration or temperature can alert you to investigate for imbalance, misalignment, looseness, and late-stage bearing wear. Identify equipment wear or performance degradation by comparing vibration measurement trends from data captured over time.

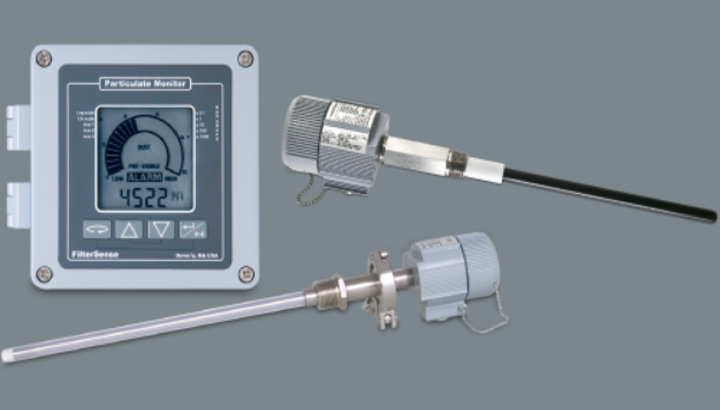

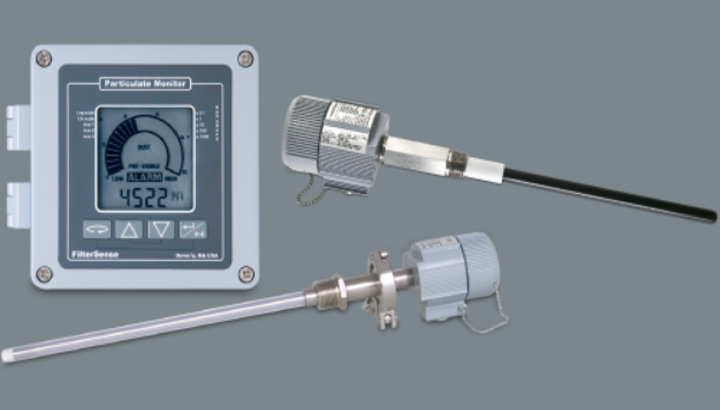

Particulate Monitoring

If conditions are not controlled ideally in the filter, bags can become degraded and burst. This is a critical environmental and production hazard. A single non-contact dust detector in the clean air stream can instruct the operator or take instant action to avoid contamination of the outside air.

Enhanced Sensing Solutions for FS Dust Collectors

Humidity Sensors

Hot gas in the Foundry or Smelting operation may have high moisture content. If the gas temperature drops below the dewpoint, serious clogging can occur that damages filter bags and may cause corrosion. An effective and rugged humidity sensor can track key points and report on problem areas.

Fan Performance

Measuring fan vibration and bearing temperature provides an early warning for potential equipment faults. Changes in vibration or temperature can alert you to investigate for imbalance, misalignment, looseness, and late-stage bearing wear. Identify equipment wear or performance degradation by comparing vibration measurement trends from data captured over time.

Particulate Monitoring

If conditions are not controlled ideally in the filter, bags can become degraded and burst. This is a critical environmental and production hazard. A single non-contact dust detector in the clean air stream can instruct the operator or take instant action to avoid contamination of the outside air.

Enhanced Sensing Solutions for RAF Dust Collectors

Without remote monitoring, frequent in-person operational assessments are required. Sensor technology coupled with cellular data and digital dashboards allow remote assessment of filters.

The RAF dust collector is usually installed outdoors, requiring climbs of over 25ft. and special protective gear. Service and maintenance outside the collector or inside the walk-in plenum are made even more risky in extreme cold, ice or summer storm activity. Remote sensing avoids accident claims and lost time injuries.

What’s included in MikroPul-Assist for RAF?

- Non-Clogging Differential Pressure

- Dust Emissions Probe

- Zero Speed Switch - Cleaning Assembly

- Fan Motor Amps

- Zero Speed Switch - Rotary Air Lock

- Cellular Gateway Package incl. Panel and sensor I/O

- 5 Insight Dashboard User licenses

- Dashboard and Gateway configuration

*Does not include electrical wiring onsite

Additionally, each 2 year MikroPul-Assist agreement includes a cellular data connection, phone support for the dashboard application and 4 hours of remote technician support for the dust collector.

A smarter solution, deep insights

We are continuing to develop Nederman Insight, adding advanced modules that give you greater functionality and more valuable insights into your air filtration system.

Action Center

Track filtration system performance and quickly identify issues. Full overview of filter operation via one or more dashboards with drill-down functions. Cloud-based data storage for remote monitoring from mobile devices.

Events Notification

A rules engine automatically triggers user notifications when any value moves outside of a defined, acceptable range. Event logs track alarm acknowledgement, action taken, and maintenance recommendations.

Historical Data Log

Identify filter performance trends using data collected over time. Track spare parts usage, accurately predict filter media life, and establish performance benchmarks. Collect data for health, safety and environmental audits.

Machine Learning (Developing)

Smart algorithms look for complex and seemingly unrelated patterns in your data to identify previously undetected risks. Root cause analysis tools uncover underlying issues and create a process of continuous improvement.

Workflow Engine (Developing)

Client-defined workflows keep everyone working as a team to accomplish common goals. Create time- or activity-dependent tasks for your maintenance staff and MikroPul technicians based on filter conditions.

Reporting (Developing)

Enables you to extract more sophisticated, customized reports and gain insights into areas such as system performance, sustainability targets and investment requirements.